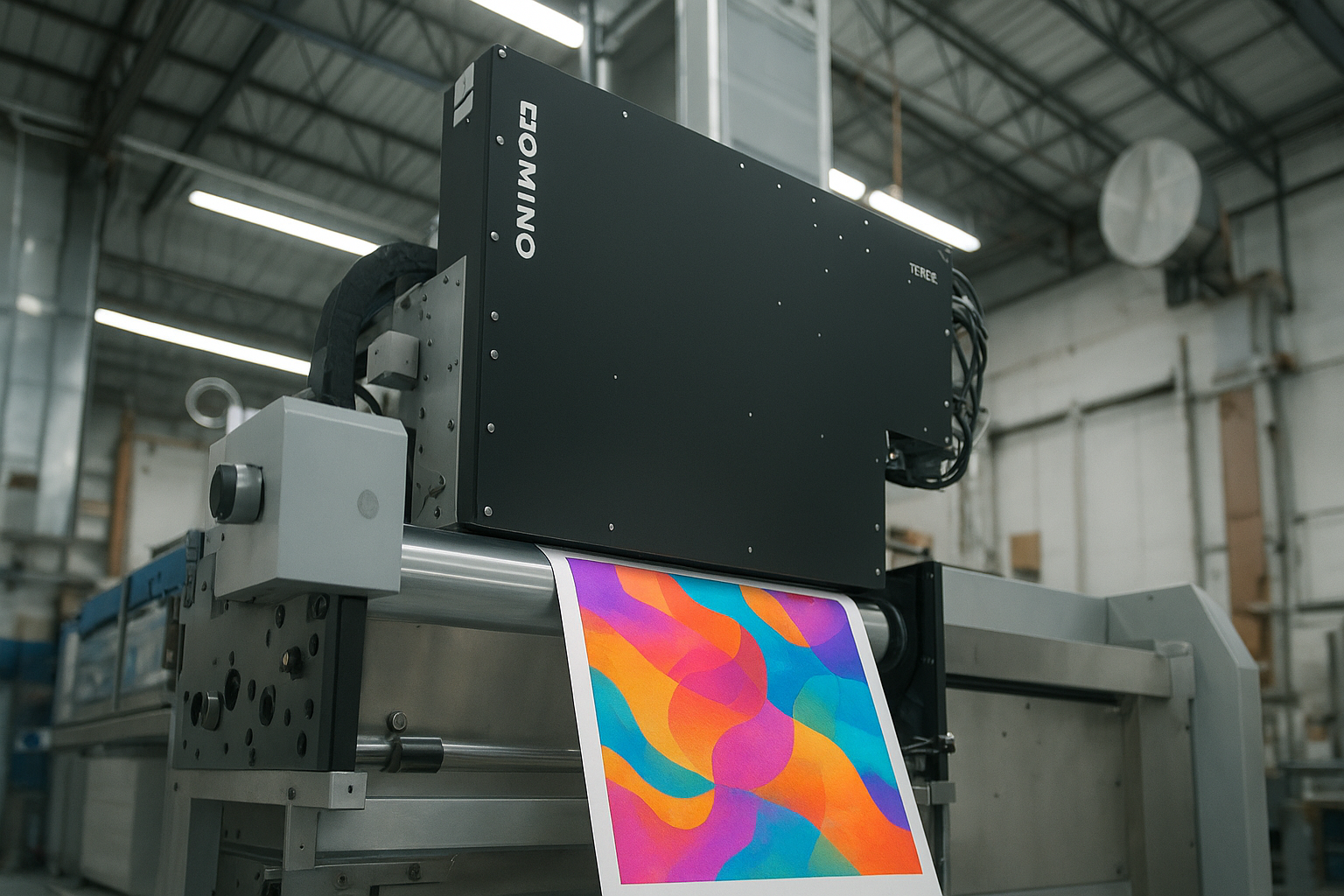

Prepress

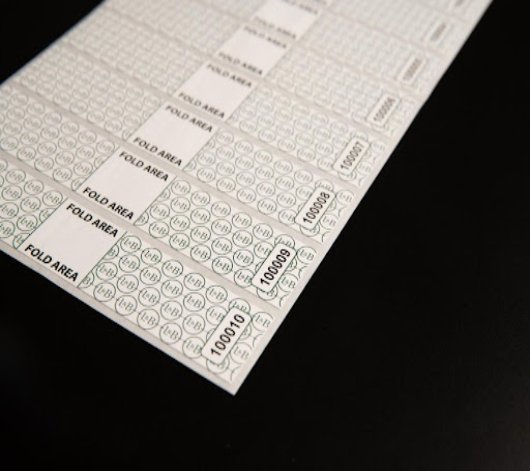

A full compliment of in-house prepress ensures your artwork is production-ready through precision readiness. From file formatting and plate making to barcodes, serialization, and limitless design adjustments, we use the latest technology to bring your vision to life and guarantee flawless printing.